Process Heaters

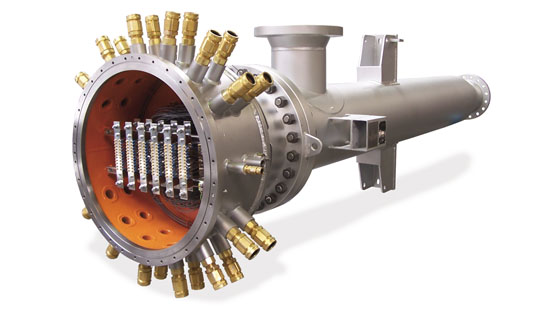

Process heater type series SDRC/DRC

Planned and manufactured according to customer specification, type series SDRC/DRC is extreme versatile. This type series was developed especially for the requirements of our customers from the chemical,

petrochemical, and refinery industries, that is, for operating companies for which/in which explosion protection plays a central role.

Their essential performance feature is robustness, which is reflected in the selection of the explosion protection concept. The available range of materials of parts that come into contact with media extends from unalloyed steels and alloyed heat-resistant grades to high-alloy stainless steels and nickel-based alloys.

Area of application

- Heating of all kinds of liquids and gases for mounting and operation in explosive atmospheres.

Functional principle

- Continuous heating of the medium through the exchange of heat between the tubular heater and the medium. Our know-how consists of adapting the heat exchange surface individually and optimally to the operating

conditions to guarantee that the process temperature is reached without the permissible heating surface temperature or permissible pressure loss being being exceeded.

Technical data

Characteristic data

- Heating capacity up to 2 MW (even higher in modular construction)

- Operating temperature: up to 700 °C

- Operating pressure: according to customer requirement

- Approval: Zone 1, gas groups IIA, B, C (ATEX prototype test Ex II2 G)

- Design: “Ex d” adapter box, IP66; T1-T6

- Ambient temperature: -50 °C to +60 °C

- Supply voltage: max. 690 V/AC

Manufacturing standard

- PED 97/23/EG

- EN 13445

- AD-2000 code of practice

- ASME VIII Div. 1

- GOST TR, RTN